Popcorn Equipment

With more than $1 billion in annual retail sales, popcorn is not only one of the hottest growing snack foods in America; it’s becoming a global phenomenon. Popcorn fits into the better-for-you snack trend as a low-calorie food with a myriad of flavoring possibilities.

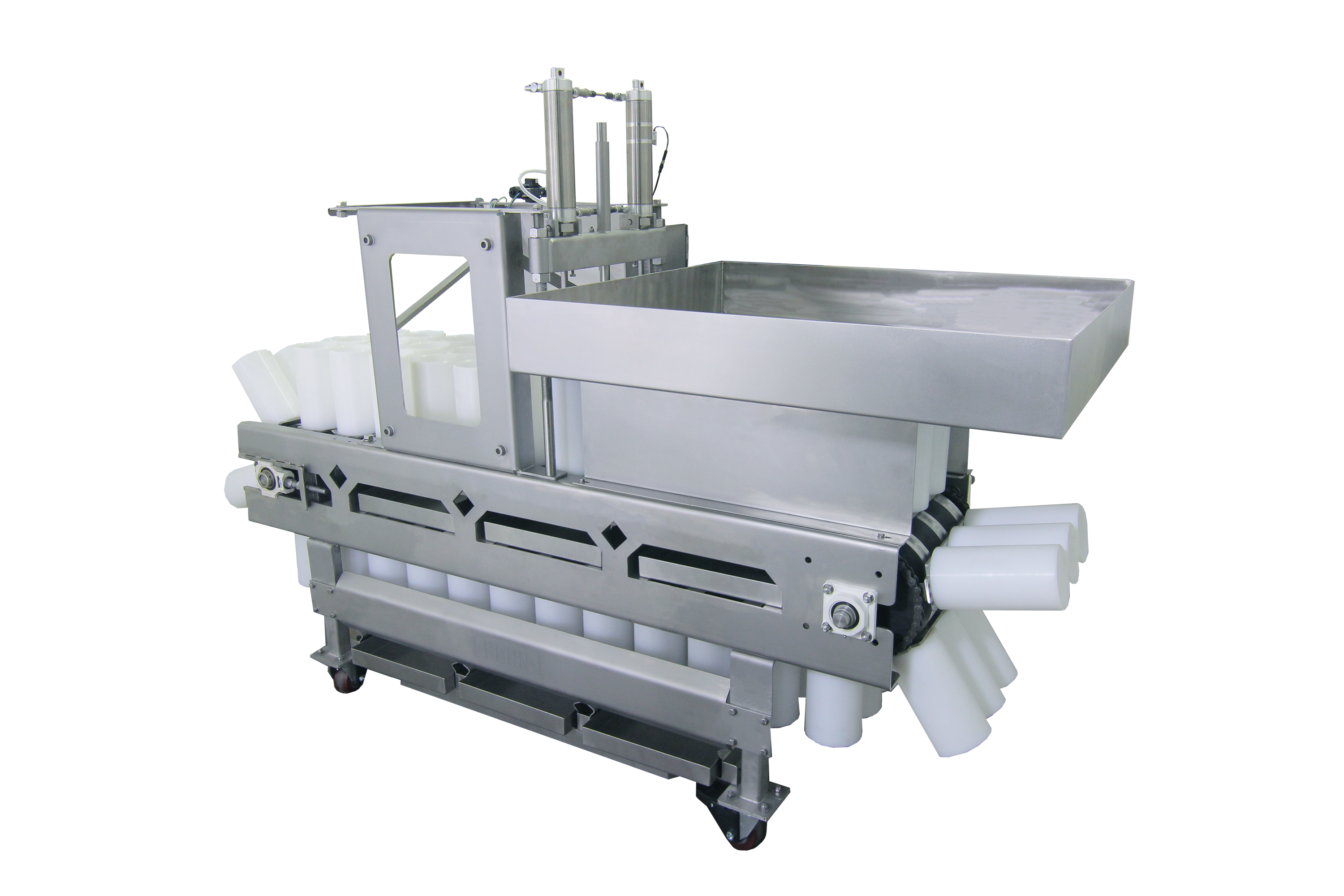

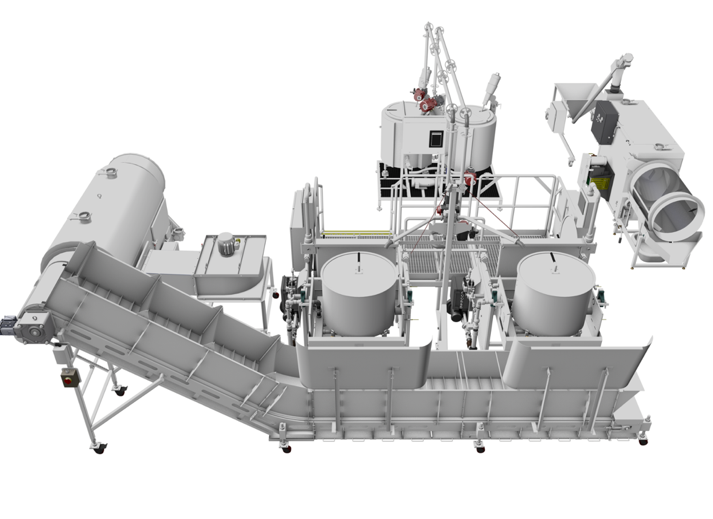

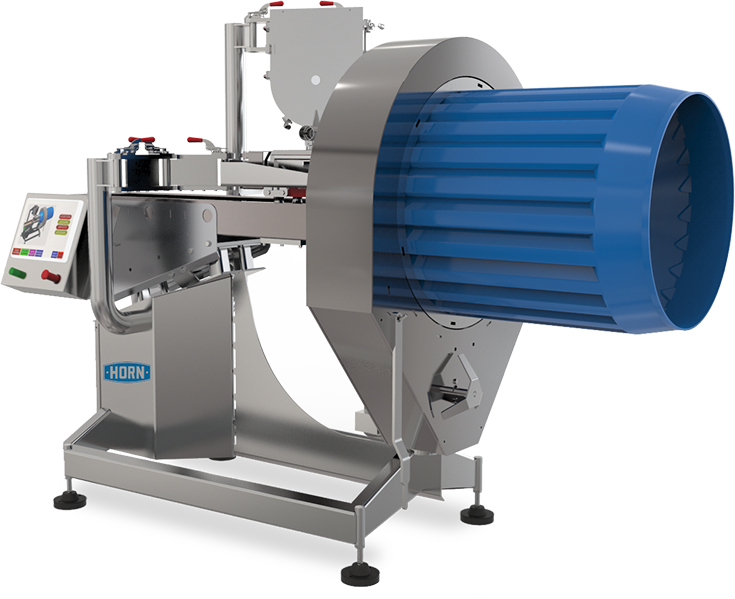

Processing equipment

Food processors from around the world rely on AC Horn Manufacturing to build, ship and service the equipment they need to take advantage of this snack market opportunity. Horn owns the best reputation for quality and reliability, serving medium to large-sized popcorn processors. This market concentration on industrial-sized snack processors gives Horn an unparalleled depth of experience to understand the special requirements and needs of this unique customer base.

When we sell a piece of equipment, it marks the beginning of a business relationship, not the end of a transaction. We believe in superior service and swift response to customer requests from planning, through construction and shipping and for years following installation.

Horn industrial poppers are built with longevity in mind. Robust and durable, each piece has an anticipated lifespan of at least 20 years. Every piece of Horn equipment is designed for optimal plant safety and sanitation, ease of operation and minimal maintenance.

How to Make Caramel Popcorn

How to Make Kettle Corn